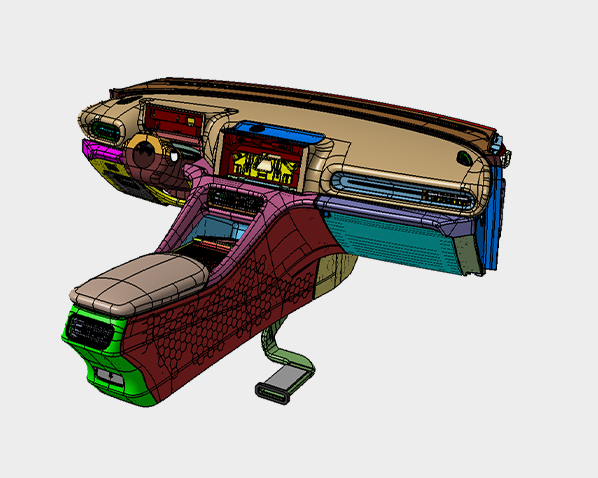

Interior Component Applications

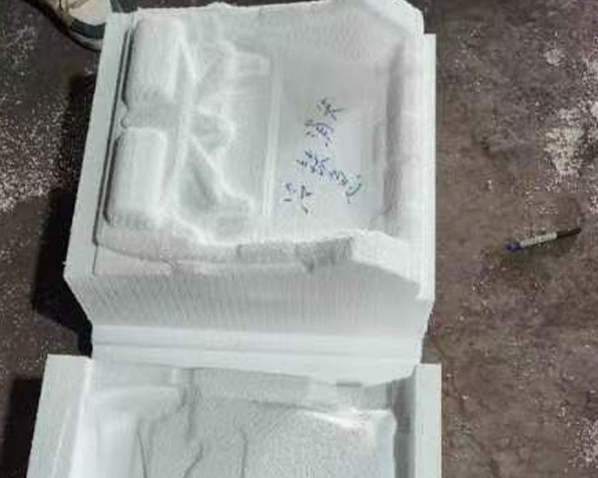

- Instrument Panel (Dashboard) Passenger Airbag Cover Dashboard Main Body/Upper Cover Center Console Panels/Trim Accents

- Door Panels Door Panel Main Body/Map Pocket Armrest/Decorative Panel

- Other Interior Components Headliner/Interior Lining: Seat Back Panels Trunk Side Panels/Trim A/B/C Pillar Trims